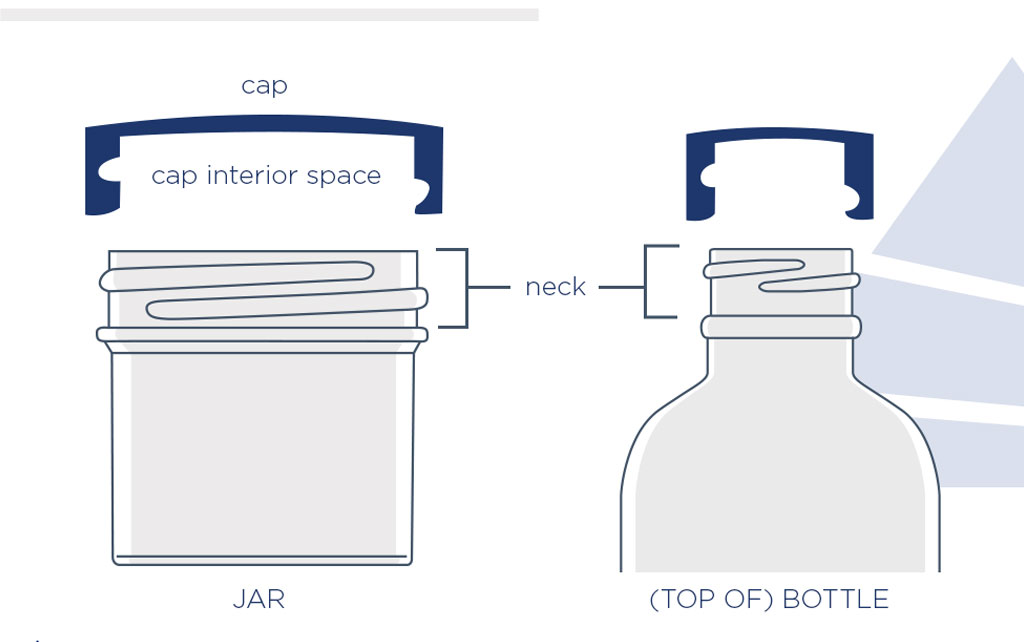

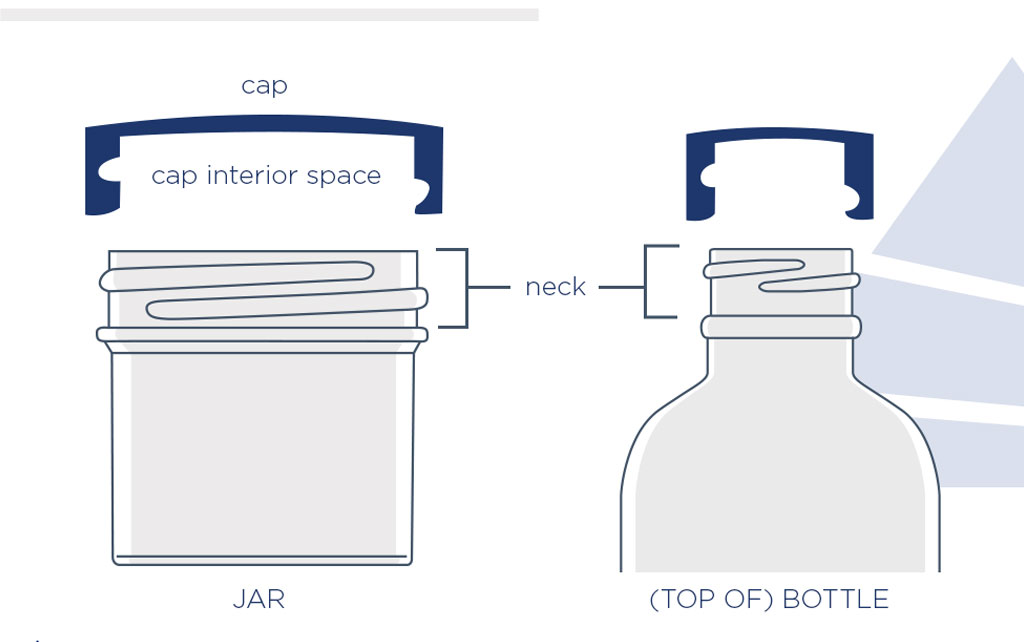

In the cosmetic industry, bottle and jar neck finishes and sizes are crucial for ensuring compatibility with various closures such as caps, pumps, and sprayers.

Understanding these components is essential for both manufacturers and consumers to ensure compatibility with closures and ease of use.

Neck Finishes

The neck finish of a cosmetic bottle or jar refers to the shape and design of the top opening where the closure (such as a cap, pump, or sprayer) is applied. Here are the common neck finishes in the cosmetic industry:

Continuous Thread (CT):

- Description: This is the most common type of neck finish. It features a continuous spiral thread that allows a cap or closure to be screwed on tightly.

- Advantages: Easy to use, secure closure, and widely available in various sizes.

- Applications: Often used for lotions, creams, and other skincare products.

Crimp Neck:

- Description: This neck finish is typically used for aerosol cans and certain perfume bottles. The closure is crimped onto the neck of the bottle.

- Advantages: Provides a tamper-evident seal and is suitable for pressurized products.

- Applications: Perfumes, deodorants, and spray products.

Snap-On:

- Description: A snap-on neck finish allows the closure to be pressed or snapped onto the bottle or jar without twisting.

- Advantages: Quick and easy to apply.

- Applications: Creams, gels, and other products with a thicker consistency.

Crimp-On:

- Description: Combines features of both crimp and snap-on finishes, offering versatility for different types of closures.

- Advantages: Provides a secure fit and can be used with many other closure types.

- Applications: High-end cosmetics and personal care products.

Roll-On:

- Description: Used for products that are applied with a rolling ball mechanism.

- Advantages: Allows controlled application of the product.

- Applications: Deodorants, perfumes, and eye serums.

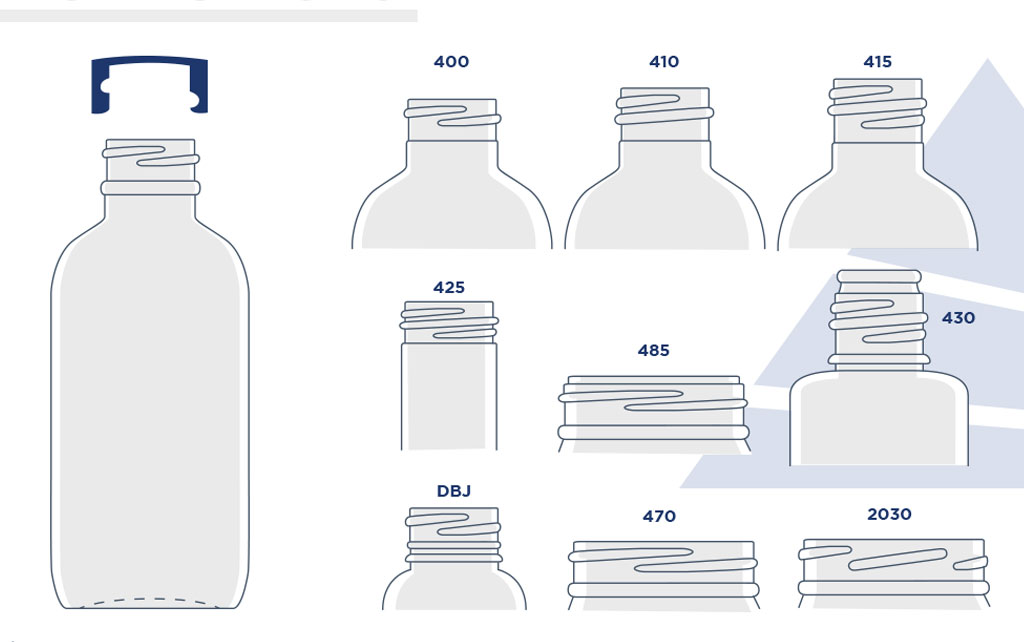

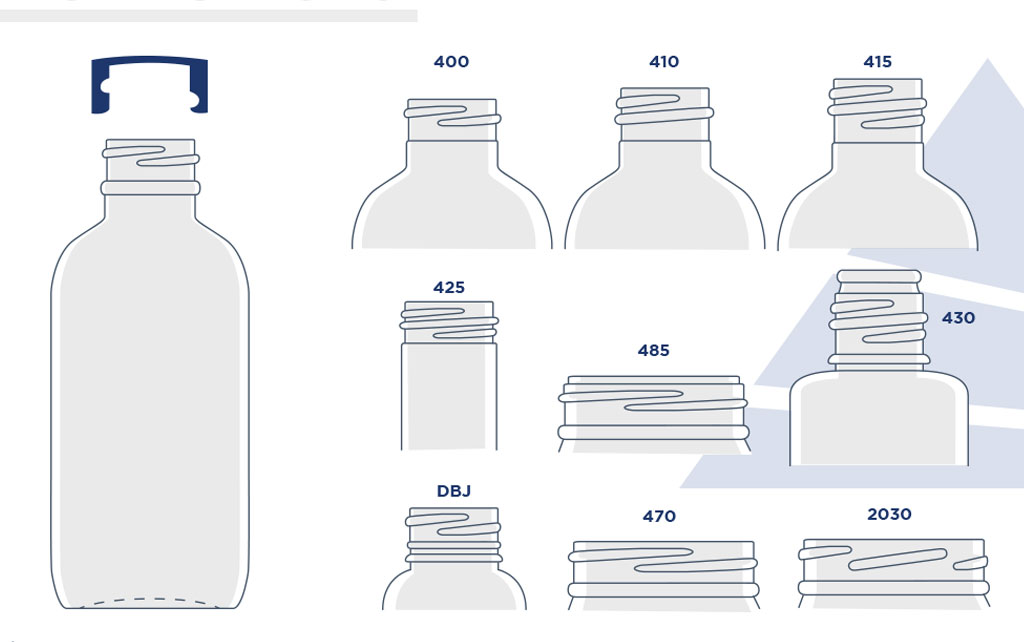

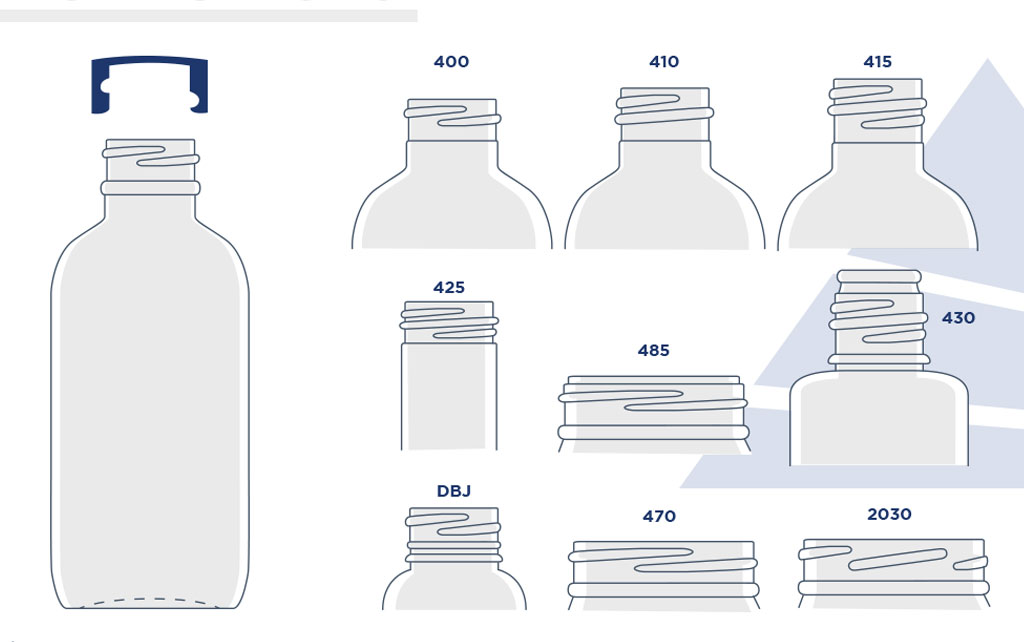

Neck Sizes

The neck size of a cosmetic bottle or jar is typically indicated by two numbers: the diameter of the neck opening and the height of the neck finish. They are crucial for ensuring that the closure fits properly. Here are some common neck sizes:

18/400:

- Description: The first number (18) represents the diameter in millimeters, and the second number (400) indicates the height of the neck finish.

- Applications: Small bottles for serums, essential oils, and other concentrated products.

20/410:

- Description: Slightly larger than the 18/400, suitable for a wide range of products.

- Applications: Lotions, shampoos, and conditioners.

24/410:

- Description: Common for medium-sized bottles.

- Applications: Hand creams, facial cleansers, and body lotions.

28/410:

- Description: Larger neck size, often used for bottles that require a pump dispenser.

- Applications: Body washes, hair care products, and other liquid products.

33/400:

- Description: A larger diameter, suitable for jars as well as bottles.

- Applications: Creams, masks, and scrubs.

38/400:

- Description: One of the largest common neck sizes.

- Applications: Bulk products, refills, and large containers.

Importance of Compatibility

Choosing the right neck finish and size is crucial for the functionality and consumer experience of cosmetic products. Incompatibility can lead to issues such as leakage, contamination, and consumer dissatisfaction.

By meticulously following these steps and ensuring attention to detail at each stage, you can achieve perfect neck finishes and size fits for cosmetic bottles and jars.

Measuring the Neck and Closure:

- Diameter: Measure the outer diameter of the bottle's neck and the inner diameter of the closure. They should match according to the neck finish code.

- Thread Design: Check the thread count and style. Different closures might have varying thread counts and styles even if the diameters match.

- Height: The height of the neck finish must match the closure to ensure a secure fit.

Testing and Prototyping:

- Leak Testing: Conduct leak tests by filling the bottles with the product and securing the closure. Observe for leaks over time.

- Drop Testing: Perform drop tests to ensure the bottle and closure can withstand impacts without breaking or leaking.

- Consumer Testing: Gather feedback from consumers on the ease of use, comfort, and functionality of the bottle and closure.

Adjusting Design:

- Tolerance Adjustments: Adjust the tolerances in the design to ensure a snug fit. This might involve tweaking the dimensions slightly.

- Thread Depth and Pitch: Fine-tune the thread depth and pitch to ensure smooth and secure closure.